Reasons and maintenance plan for motor vibration

Ten reasons for vibration

1. Caused by rotor, coupler, coupling, and transmission wheel (brake wheel) imbalance.

2. Loose iron core support, failure and looseness of inclined keys and pins, and loose binding of rotors can all cause imbalance in the rotating parts.

3. The axis system of the linkage part is not centered, the centerline is not aligned, and the centering is incorrect. The main cause of this malfunction is due to poor alignment and improper installation during the installation process.

4. The centerline of the linkage part is coincident and consistent in the cold state, but after running for a period of time, the centerline is damaged due to deformation of the rotor fulcrum, foundation, etc., resulting in vibration.

5. Malfunctions in the gears and couplings connected to the motor, poor gear engagement, severe tooth wear, poor wheel lubrication, skewed or misaligned couplings, incorrect tooth profile and pitch, excessive clearance, or severe wear of gear couplings can all cause certain vibrations.

6. Defects in the structure of the motor itself, such as elliptical shaft neck, bent shaft, excessive or insufficient clearance between the shaft and the bearing shell, insufficient stiffness of the bearing seat, foundation plate, certain parts of the foundation, and even the entire motor installation foundation.

7. Installation issues include weak fixation between the motor and the foundation plate, loose foot bolts, and loose connections between the bearing seat and the foundation plate.

8. Excessive or insufficient clearance between the shaft and the bearing shell can not only cause vibration, but also lead to abnormal lubrication and temperature of the bearing shell.

9. The load driven by the motor conducts vibration, such as the vibration of the fan and water pump driven by the motor, causing the motor to vibrate.

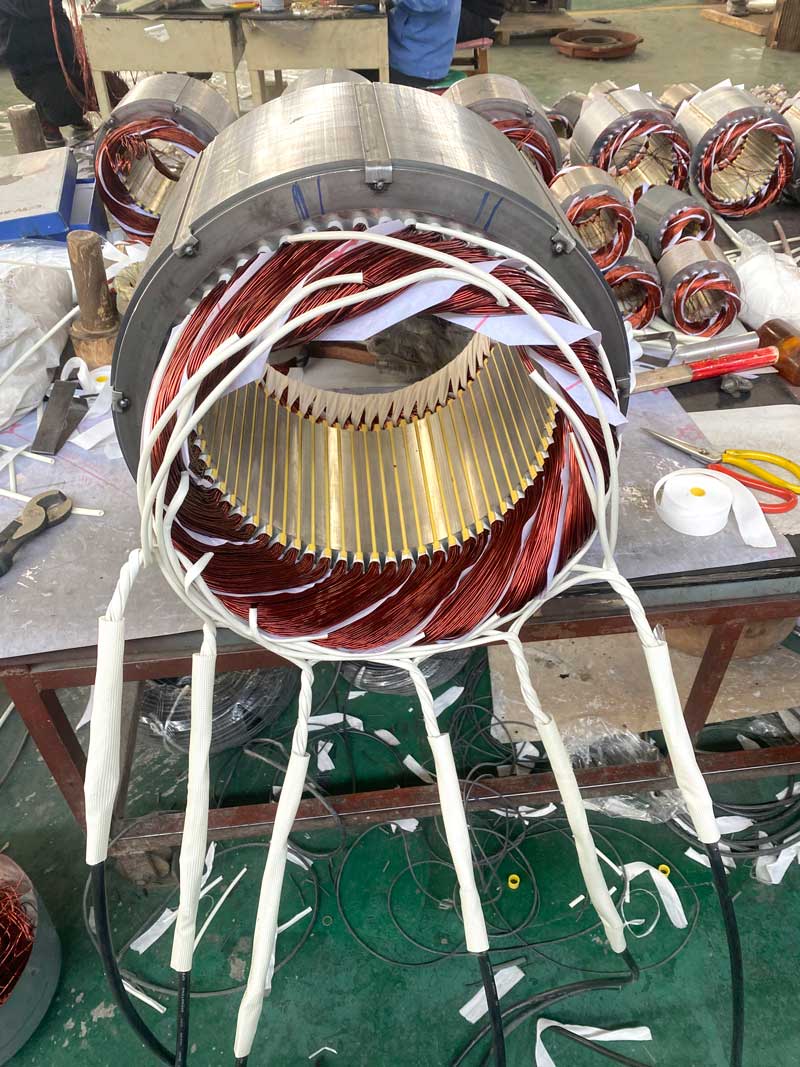

10. The stator wiring of the AC motor is incorrect, the rotor winding of the wound asynchronous motor is short circuited, the excitation winding of the synchronous motor is short circuited between turns, the excitation coil of the synchronous motor is connected incorrectly, the rotor of the cage asynchronous motor is broken, and the deformation of the rotor iron core causes uneven air gap between the stator and rotor, resulting in unbalanced magnetic flux in the air gap and causing vibration.

How to find the cause of vibration

1. Before the motor is stopped, use a vibration meter to check the vibration situation of each part. For parts with high vibration, test the vibration values in detail in three directions of vertical and horizontal axis. If the foundation screws are loose or the bearing end cap screws are loose, they can be directly tightened. After tightening, measure the vibration size and observe whether it is eliminated or reduced. Secondly, check whether the three-phase voltage of the power supply is balanced and whether the three-phase fuse is burnt. Single phase operation of the motor can not only cause vibration, but also quickly increase the temperature of the motor. Observe whether the ammeter pointer swings back and forth, and whether the current swings when the rotor bar breaks. Finally, check whether the three-phase current of the motor is balanced. If any problems are found, contact the operator in a timely manner to stop the motor operation to avoid burning the motor.

2. If the surface phenomenon is treated and the motor vibration is not resolved, continue to disconnect the power supply, loosen the coupling, and mechanically separate the motor from the load connected to it. For a single rotation motor, if the motor itself does not vibrate, it indicates that the vibration source is caused by the coupling not being aligned or the load machinery. If the motor vibrates, it indicates that there is a problem with the motor itself. In addition, the power outage method can be used to distinguish between electrical and mechanical reasons. When the power outage occurs, if the motor immediately stops vibrating or the vibration is reduced, it indicates that it is an electrical problem, otherwise it is a mechanical failure.

Conduct maintenance based on the cause of the malfunction

1. Maintenance for electrical reasons

The first step is to determine whether the three-phase DC resistance of the stator is balanced. If it is unbalanced, it indicates that there is a welding phenomenon at the welding part of the stator connection. Disconnect the winding phase and search for it. In addition, check whether there is a short circuit between turns in the winding. If the fault is obvious, burn marks can be seen on the insulation surface, or measure the stator winding with an instrument. After confirming the short circuit between turns, rewire the motor winding.

2. Maintenance due to mechanical reasons

Check if the air gap is uniform. If the measured value exceeds the standard, readjust the air gap. Check the bearings, measure the bearing clearance, replace the bearings with new ones if they are not qualified, inspect the deformation and looseness of the iron core, and use epoxy resin adhesive to bond and compact the loose iron core. Check the shaft, weld and reprocess the bent shaft or directly straighten it, and then conduct a balance test on the rotor.

3. The mechanical part of the load has been checked and found to be normal, and there are no issues with the motor itself

The cause of the malfunction is due to the connection part. At this time, it is necessary to check the basic horizontal plane, inclination, strength, center alignment of the motor, whether the coupling is damaged, and whether the motor shaft extension meets the requirements.

Steps for handling motor vibration

1. Disconnect the motor from the load, test the motor empty, and measure the vibration value.

2. Check the vibration value of the motor foot. The vibration value at the foot plate should not exceed 25% of the corresponding position of the bearing. If it exceeds this value, it indicates that the motor foundation is not a rigid foundation.

3. If only one of the four footings or two diagonal ones exceed the vibration limit, loosening the anchor bolts will result in qualified vibration, indicating that the footings are not properly padded. Tightening the anchor bolts will cause deformation and vibration of the machine base. Tighten the footings, align them correctly, and tighten the anchor bolts.

4. Tighten all four anchor bolts on the foundation, but the vibration value of the motor still exceeds the standard. At this time, check whether the coupling installed on the shaft extension is flush with the shaft shoulder. If it is uneven, the excitation force generated by the excess keys on the shaft extension will cause the motor to vibrate horizontally beyond the standard. In this situation, the vibration value will not exceed too much, and often the vibration value can decrease after docking with the host. If it needs to be processed, simply cut off the excess keys to make them longer.

5. If the vibration of the motor during the empty test does not exceed the standard, but the vibration with the load exceeds the standard, there are two reasons: one is that there is a large deviation in the alignment; Another type is that the residual unbalance of the rotating components (rotor) of the host and the residual unbalance of the motor rotor overlap in phase, resulting in a large residual unbalance of the entire shaft system at the same position after docking, which generates a large excitation force and causes vibration. At this point, the coupling can be disconnected, and either of the two couplings can be rotated 180 ℃ before being connected to the test machine. The vibration will decrease.

6. The vibration velocity (intensity) does not exceed the standard, and the vibration acceleration exceeds the standard, so the bearing can only be replaced.

7. Due to poor rigidity, the rotor of a high-power motor with two poles may deform if not used for a long time, and may vibrate when turned again. This is the reason for poor motor storage. Under normal circumstances, a two pole motor should be stored during storage. Every 15 days, the motor should be turned and rotated at least 8 times each time.

8. The motor vibration of sliding bearings is related to the assembly quality of the bearing shells. It is necessary to check whether there are high points in the bearing shells, whether the oil inlet of the bearing shells is sufficient, the tightening force of the bearing shells, the clearance between the bearing shells, and whether the magnetic centerline is appropriate.

9. In general, the cause of motor vibration can be simply judged from the vibration values in three directions: large horizontal vibration and rotor imbalance; Vertical vibration is large, and the installation foundation is uneven and not good; Large axial vibration and poor quality of bearing assembly. This is just a simple judgment. We need to consider the on-site situation and the factors mentioned above comprehensively to find the true cause of the vibration.

10. Special attention should be paid to the axial vibration of the Y series box type motor. If the axial vibration is greater than the radial vibration, it will cause great harm to the motor bearings and lead to shaft holding accidents. Attention should be paid to observing the temperature of the bearings. If the temperature rise rate of the locating bearings is faster than that of the non locating bearings, the machine should be stopped immediately. This is due to insufficient axial stiffness of the machine base causing axial vibration, and the machine base should be reinforced.

11. After dynamic balancing, the residual unbalance of the rotor has solidified on the rotor and will not change, and the vibration of the motor itself will not change with the location and working conditions. In general, it is not necessary to perform dynamic balance verification on the motor during maintenance, except for extremely special circumstances such as flexible foundations, rotor deformation, etc., which require on-site dynamic balance or return to the factory for processing.